As the Additive Manufacturing industry has quickly evolved, many organizations are evaluating options and technologies to speed up their design and engineering needs. Choosing the right technology, material, and application can be a daunting and expensive task. To help develop the right business case, or to keep capital and operating expenses down, many users are turning to additive manufacturing services to augment their internal capabilities and narrow the technology and application requirements for project success. This can be a path to eventually bringing Additive Manufacturing in-house, in a controlled investment that can bring immediate value.

With the fast evolution of digital communications and innovation, it is evident that technology can shape the world around us. Conventional manufacturing has evolved to advanced and distributed production processes, increasing the efficiency and effectiveness of business operations, considering the effects on the environment, enhancing human health and lifestyle through extended options or customization, or simply making life more comfortable. We added engineering services and 3D printing services to our portfolio – as we believe that professionals equipped with advanced tools can give their businesses the flexibility and speed to solve the challenges they are facing.

We segmented 3DGence Services into 3 pillars:

Similar to conventional subtractive manufacturing methods, additive manufacturing provides a wide range of technologies to provide a final, tangible item. 3D printing is an additive manufacturing process of producing objects based on a computer model. This option encompasses a variety of technologies that make it possible to produce an item from almost any type of material: Plastics, metals, ceramics, and even composites – often much faster and at less cost – regardless of design complexity.

The currently available AM technologies at 3DGence:

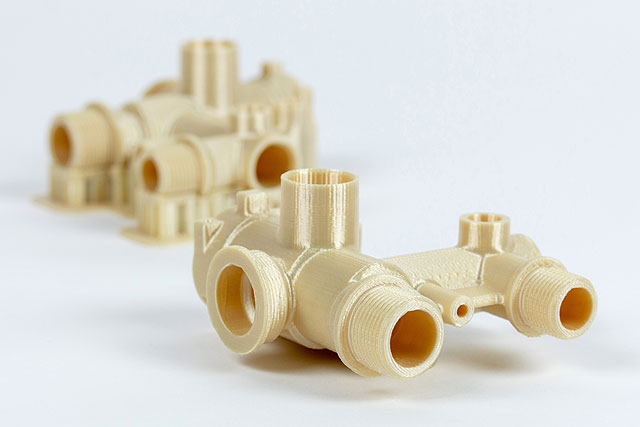

It involves the application of layers, path by path, made of thermoplastic (polymer) materials. The high temperature of the material extruder melts the polymer, which enables building the set geometry layer by layer. This technology allows you to manufacture elements from different types of polymers, giving FFF a broad spectrum of applications and bringing a significant range of design freedom. FFF offers a wide range of materials from prototype grade to metal replacement/composite materials – often at a good price/quality ratio.

This technology was developed by Hewlett-Packard (HP). MJF utilizes a liquid fusing agent to consistently combine layers of powdered polymer material into a 3D shape. Inkjet heads perform the task of dispensing the liquid fusing and detailing agents throughout the process based on the part geometry. The material is then exposed to heat, fusing in selected areas to match the geometric design. MJF features high precision, efficiency, scalability, and production flexibility.

SLS incorporates a process where successive layers of applied powder (thermoplastic polymers) are sintered using a laser. The laser melts polymer powder and fuses it into a solid 3D printed part. SLS is great for prototyping and low-volume production. The obtained parts show high mechanical and chemical resistance

In terms of operating, DMLS is similar to SLS technology. The laser sinters the metal powder selectively, according to the geometric design. This technology allows the production of functional models for a variety of applications from a wide range of metallic materials and metal alloys. Complex geometries, such as conformal-cooled injection molds, machine parts, or production tools can be produced with DMLS. Among others, titanium alloys, tool steel and stainless steel, aluminum alloys, nickel-base superalloys, and precious metals are used to create objects with DMLS technology.

Similar to a 2D inkjet printer, a piezoelectric jetting head applies liquid photopolymers onto a build platform, and then the printer cures them with UV ultraviolet light. This technology makes it possible to create printouts featuring sharp precision and ultra-fine details. There is another huge benefit of PolyJet: It enables the user to create multi-material and multicolor objects. The color diversity of the prints works well, for example, in the medical industry, where colors can be used to mark different elements of anatomical models.

The original method of 3D printing. The object is created from a polymer resin, which is selectively cured with laser light. The key benefits of SLA are high surface quality, resolution, and high printing accuracy.

There are many benefits to be realized in utilizing Additive Manufacturing services. Our range of on-demand AM and Engineering Services allows you to test different technologies and see how additive manufacturing (AM) can take your product development and production to the next level. Additionally, when choosing 3DGence Services, you are assured that the right technologies and materials most suited to your needs and capabilities will be selected and utilized. Experienced AM engineers will help you choose the optimal and most cost-effective solution for your project. 3DGence offers support and service at each stage of the production cycle – design support, manufacturing prototypes, low-volume test production, and medium-volume contract manufacturing.

As part of 3DGence Services, we offer companies comprehensive support in the research and development (R&D) of a product or technology to augment your internal capabilities. Our R&D Outsourcing Services comprise the following fields:

3DGence Engineering Services supports your projects in the following areas:

• 3D Scanning (reverse engineering) – a service provided for models without documentation or models with organic shapes. 3D scanning allows you to create a model suitable for Additive Manufacturing methods.

Industrial 3D is our Business™. Since 2014, 3DGence has developed a trusted brand of high-performance industrial 3D printing technologies including hardware and software, as well as continuous collaborations in material science. We specialize in a comprehensive approach to 3D printing using thermoplastic extrusion (FFF) technology with advanced materials. Our true industrial 3D printers are used by some of the world’s top-tier organizations. Volkswagen, NASA, SAAB, Miele, Simens, Schunk, ZF, OSRAM and Microsoft are just a few examples of companies that use equipment designed and manufactured by 3DGence engineers. Our company operates worldwide, with offices in Europe (Poland, Germany) and the USA, employing seasoned AM professionals in the areas of mechanical engineering, electronics, automation, software, materials science, and project management. In addition, we have advanced technical facilities at our disposal in all the markets where we operate.

The process of engaging 3DGence Services depends on the type, scope, and complexity of the project. In most cases, the engagement process consists of the following steps:

All types of industries are benefitting from AM Engineering services. Among industrial clients that use 3DGence Services, there are companies from the aerospace, defense, medical, automotive, rail, and electronics sectors. No matter what industry you work in, you can tap into the potential of AM 3D printing, design, scanning, R&D, and other engineering services offered by 3DGence.

The project delivery of our engineering services depends on the scope and complexity of your project. We provide quotations on a specific project basis. To get an accurate scope of your project, we kindly ask you to fill in the form below, detailing any specific requirements and challenges. We can provide a complete quotation after reviewing the information and design files, or after a discovery call for our teams to share and discuss project details.

We will help you navigate your project requirements and challenges – and partner with you to ensure project success.

Contact us now to start your project!

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.