At 3DGence, we believe that when it comes to safety, there is no room for compromise. That is why offer an advanced, 3-element filter unit that protects the user and makes the printing process easier and more comfortable. This article explores filtering solutions at 3DGence machines.

The increasing trend of implementing 3D printing technology spreads across different industries. More and more companies take benefits of additive manufacturing, such as making elements on demand, cutting costs, reducing lead time, limiting obsolesce problems, or multiplying ideas for new products with rapid prototyping. The advantages of 3D printing are undisputable, however, it is important to highlight, that this method raises some challenges. Dealing with toxic fumes and odors while printing can be named as one of them.

The fact is, that some thermoplastics used for MEX/FFF 3D printing generate harmful fumes and unpleasant smells during the process of melting and dispensing. The issue concerns some materials, including such popular printing polymers as ABS, ASA, or HIPS. Each filament of this trio incorporates Styrene, which is responsible for emitting fumes while being melted. Other examples of filaments that generate volatile organic compounds (VOC) and other types of hazardous vents are PETG and Nylon. Prolonged exposure to these fumes may cause both serious health damage (e.g., lung diseases, heart problems, inflammation) and minor difficulties, such as headaches, eye and nasal tract irritation, dizziness, and fatigue.

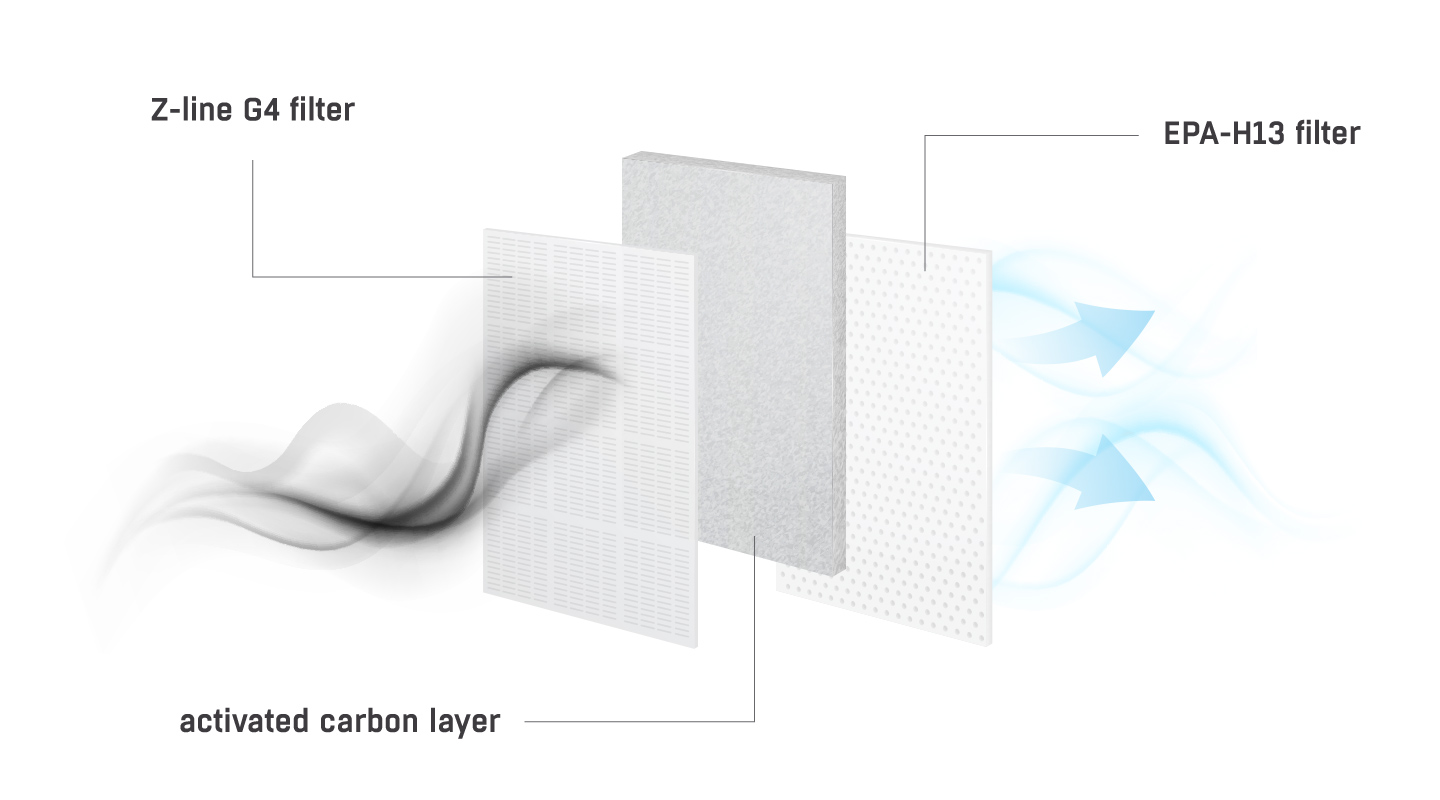

At 3DGence we address ourselves to deal with all types of challenges in FFF additive manufacturing technology. Having 9 years of experience in this field and 360⁰ approach, we perfectly understand the risk of emitting fumes and odors during the printing process. We have done our best to tackle the issue. Our clients may upgrade the flagship industrial-grade 3D printers INDUSTRY F421 and INDUSTRY F350 with advanced filtration units. Both printers possess a closed heated chamber, thus no fumes get out of the printer. An optional, 3-element filtering unit – consisting: a Z-line G4 filter, activated carbon layer, and HEPA-H13 filter – is capable of purifying nano dust (VOC, UFP), marco dust, foreign particles, solvent vapor, and noxious gases. This is one of the best possible solutions available on the market right now. This filtering unit is capable of removing the microplastic and material outgassing, absorbing VOC, and airborne Styrene. Moreover, it shields from UFP (ultrafine particles) and floating dusts PM10 and PM2.5, too. Thanks to the advanced filtration unit, the users of 3DGence printers are safe from multiple health hazards that might occur if you use a machine with inadequate protection. The professional 3D printer cares about your employees’ well-being and their motivation to work. An 8-hour shift or even a longer period spent working with 3DGence printers will not cause any discomfort and health risk for the user, keeping the operator focused and efficient.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.