FFF (Fused Filament Fabrication) technology works by depositing thermoplastic material layer by layer on

a work platform.

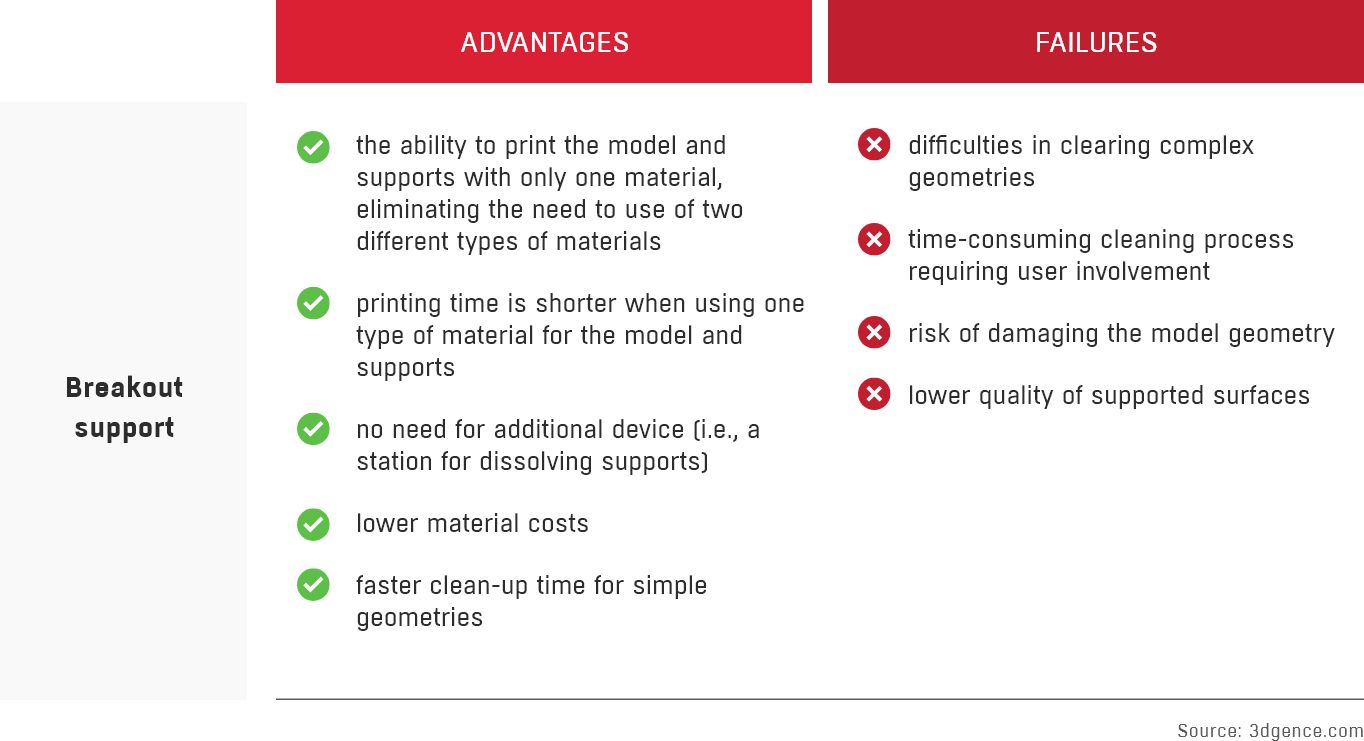

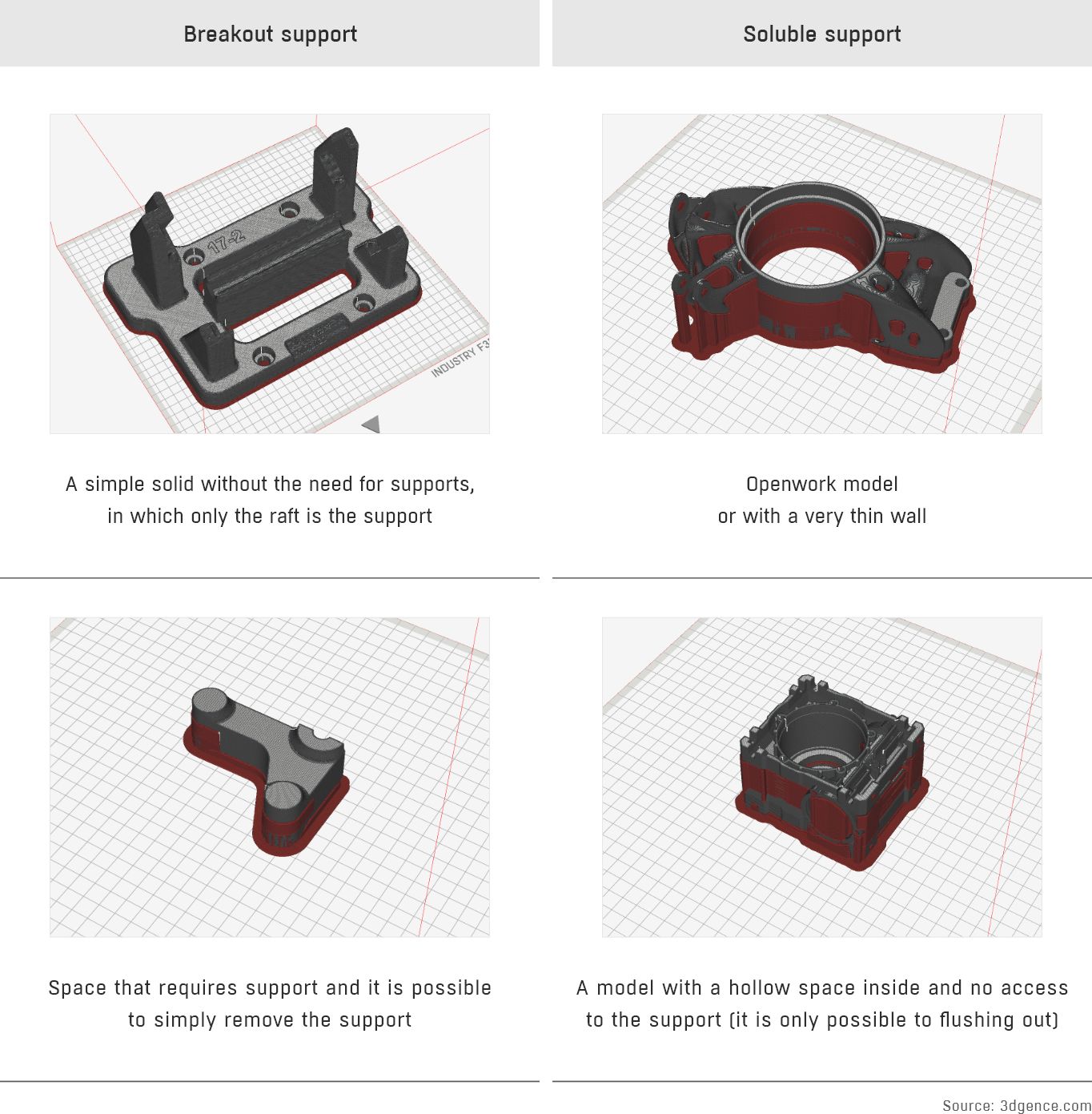

Choosing the right type of support material depends mainly on the geometry of the model. Breakout and soluble

supports have different properties.

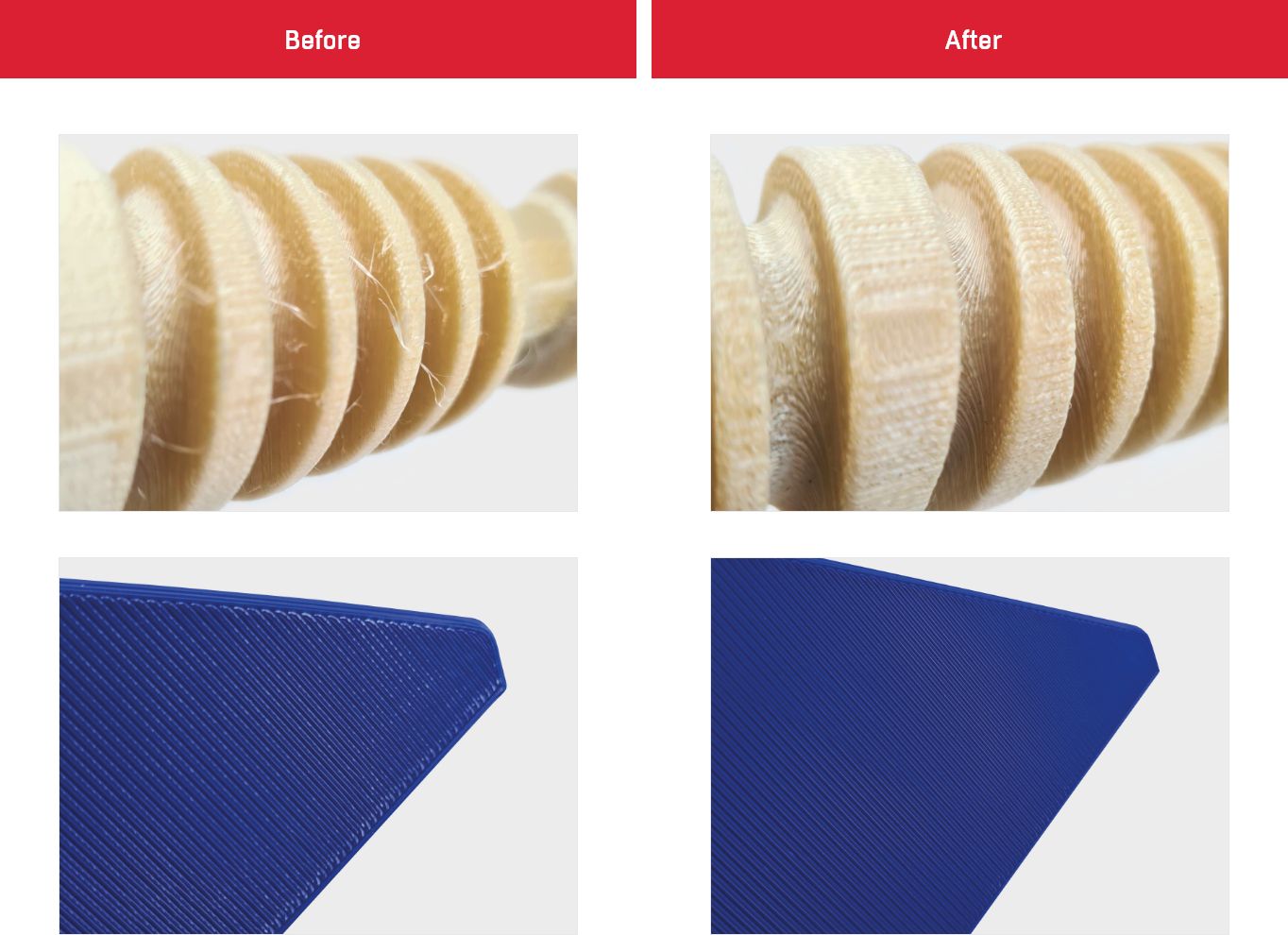

Gives the possibility to print the model and supports with only one material, eliminating the need to

use two different types of materials which translates into shorter printing time and lower material

costs. The disadvantage, however, is the time-consuming process of cleaning the model and the

risk of damaging the print geometry. This type of support can be printed from the same material as

the target model or from a different material with less adhesion to the model, making it significantly

easier to remove them.

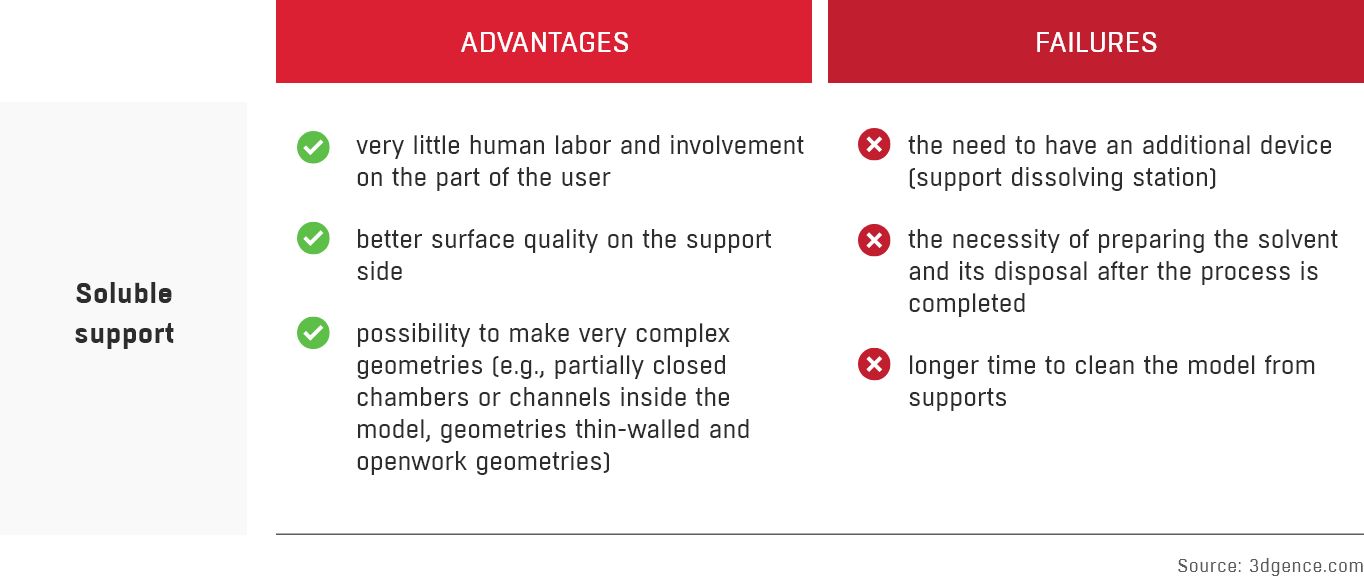

This type of structures made of dedicated support material can be dissolved by immersing the print in a

properly prepared solution. They are used in dual-head printers, especially when printing models with

complex geometry, where it is impossible or difficult to remove the supports mechanically. The dissolvable

support makes it possible to make models with very complicated geometries, such as partially closed

chambers or channels inside the model, thin-walled and openwork geometries. This method enforces the

need for of an additional device (support dissolving station) and increases the time for cleaning the model

from the supports.

In 3DGence printers, support structures can be printed using the same print head as

the target model or from an additional dedicated print head.

Before starting the printing process, it is necessary to select the appropriate support material, matching the geometry of the model. This will allow the used support

structures to be easily separated from the model after the printing process.

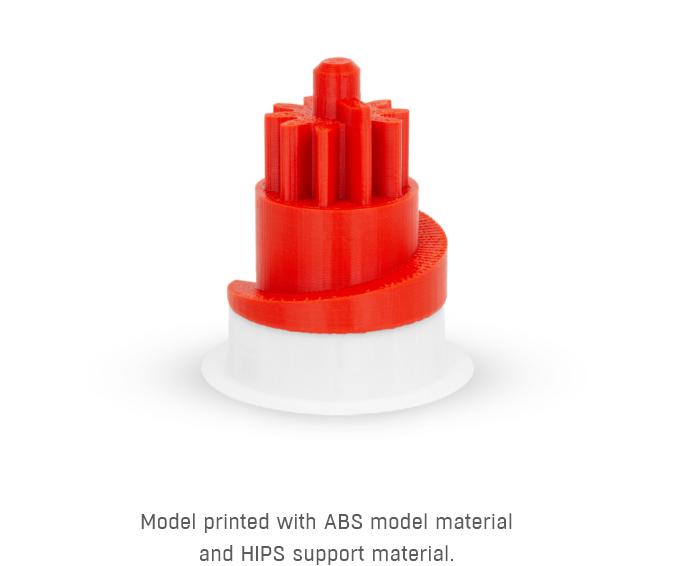

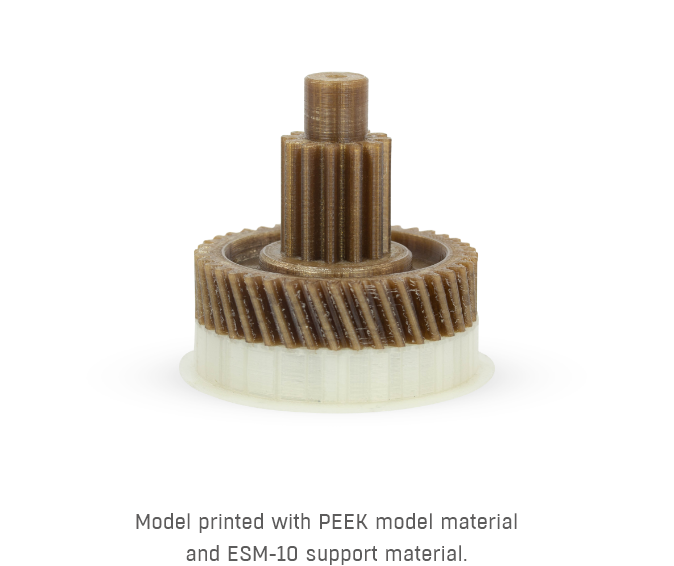

Depending on the complexity of the model geometry, we choose breakable or soluble support structures. Below

are examples of models with different support materials.

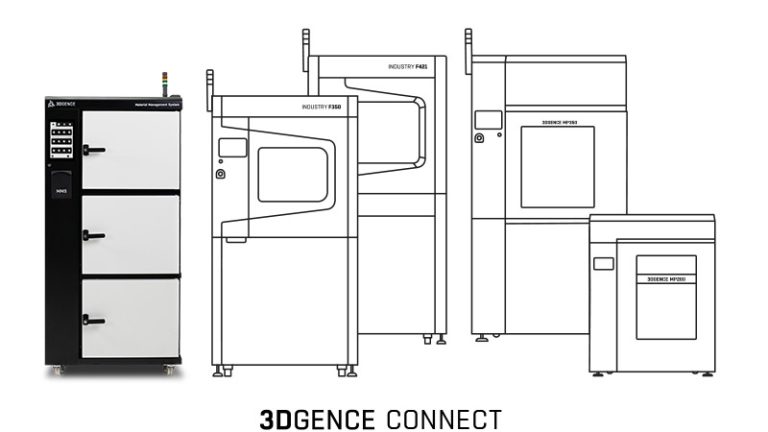

3DGence MMS automates material storage, preparation, and post-print annealing – making successful printing of Ultra-Polymers like PEEK, ULTEM™, and Composites accurate and simplified.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.