machine industry

Case study

Brzeska Fabryka Pomp i Armatury MEPROZET is a manufacturer of pumps; tank pumping stations; mixers; power and control equipment for pumps.

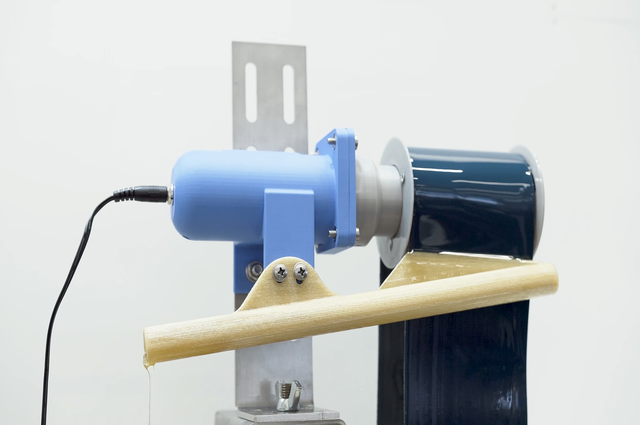

The technologists at the company decided to apply 3D printed elements in a belt oil skimmer. The device is used to remove oil build-up in the coolant.

The separating belt immersed in the liquid collects oil thanks to electrostatic adhesion.

Further, a skimmer detaches the oil from the belt and directs it to a separate tank.

The use of two different 3D printing materials (PEKK and ASA) to produce end-use parts for belt oil skimmer.

1. Reduction of maintenance costs

PEKK material is characterized by high resistance to wear, so in some applications it is able to replace elements usually made of steel or other metal alloys. The use of this filament for printing oil skimmer made it possible to obtain a replacement of grade 316 steel component. Its use enables the company to reduce the wear and tear of the transport belt. The 3D printed part on 3DGence INDUSTRY F340 reflects low abrasion in contact with oil when skimming and is resistant to most types of coolants and oils.

2. Reduction of maintenance costs

Meprozet 3D printed motor’s housing with ASA material. This filamet is characterized by increased chemical resistance to oils and greases used in the engineering industry, so it has proven itself very well in this project. 3D printing allowed the company to produce only a few housings at very low cost. Moreover, the company had the opportunity to test further iterations and adjust the product to its client.

Get the 3D printed parts you need just in time

There may be a lot of crisis situation in the future that we can’t control. 3D printing can help you with many different applications through many materials. If you have not idea what filaments will proper for your project, you can consult it with our experts: [email protected]

Get in touch with our 3D printing experts