ONE

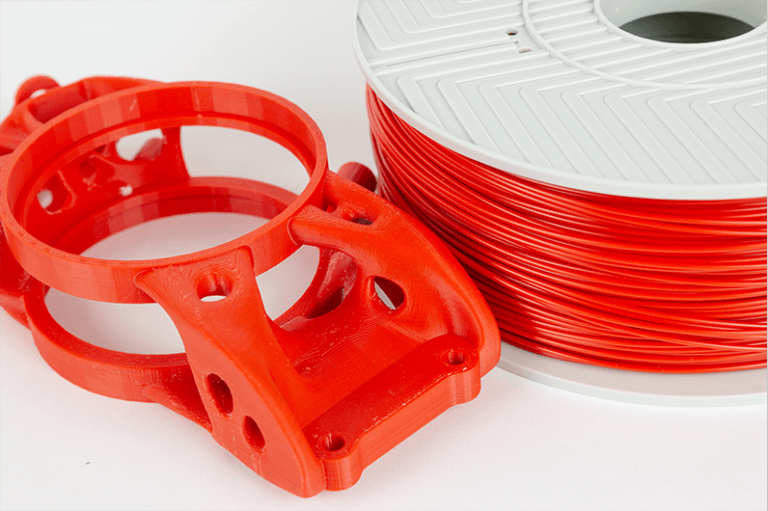

Qualität immer unter Kontrolle durch den Einsatz von patentierten Lösungen an einem 3D-Drucker. Die offene Materialdatenbank erlaubt einen Betrieb mit fast allen üblichen Materialien, darunter PLA, ASA; PP, PET, TPE.

Qualität immer unter Kontrolle durch den Einsatz von patentierten Lösungen an einem 3D-Drucker. Die offene Materialdatenbank erlaubt einen Betrieb mit fast allen üblichen Materialien, darunter PLA, ASA; PP, PET, TPE.

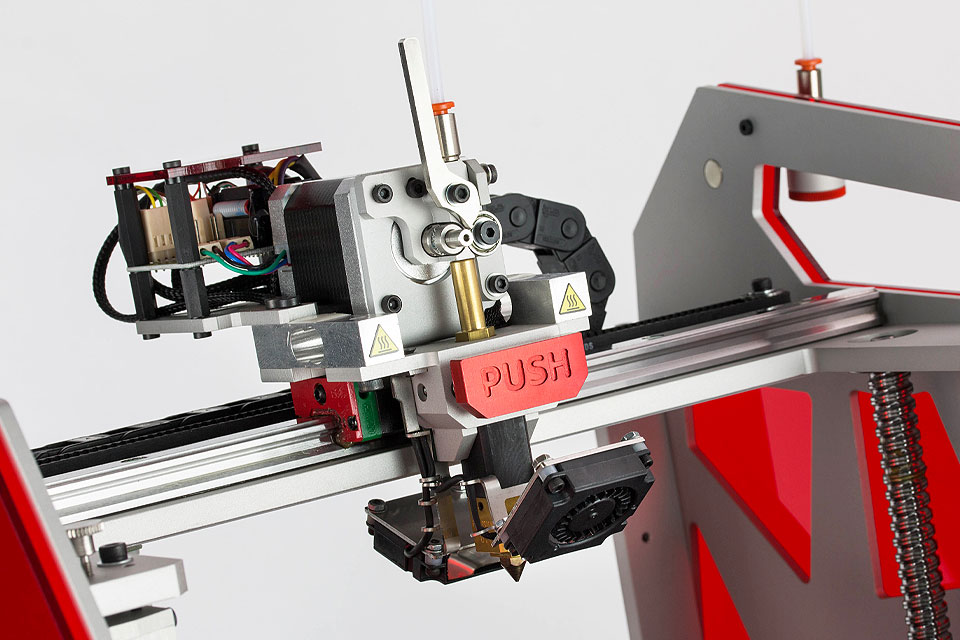

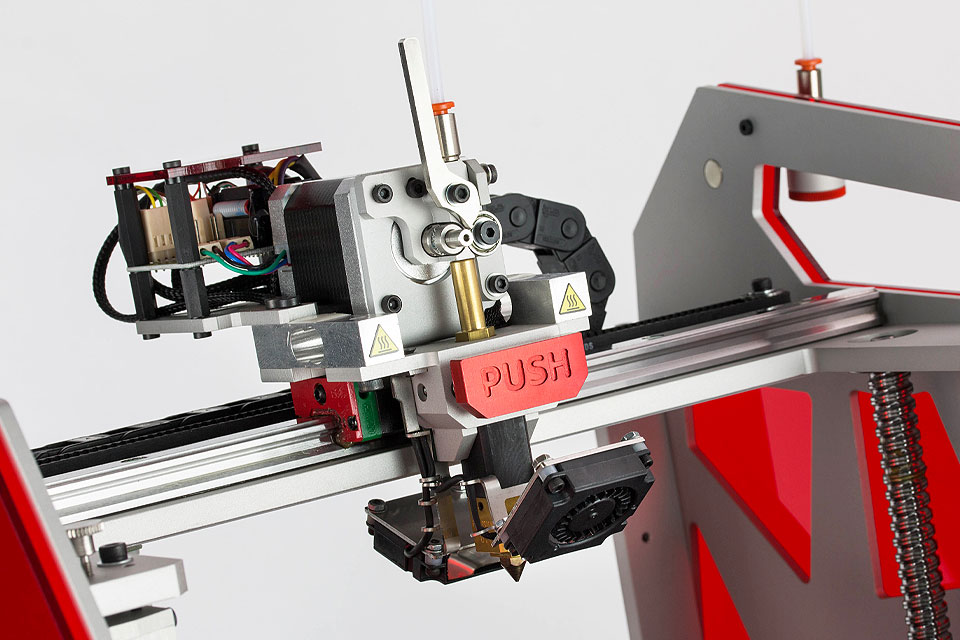

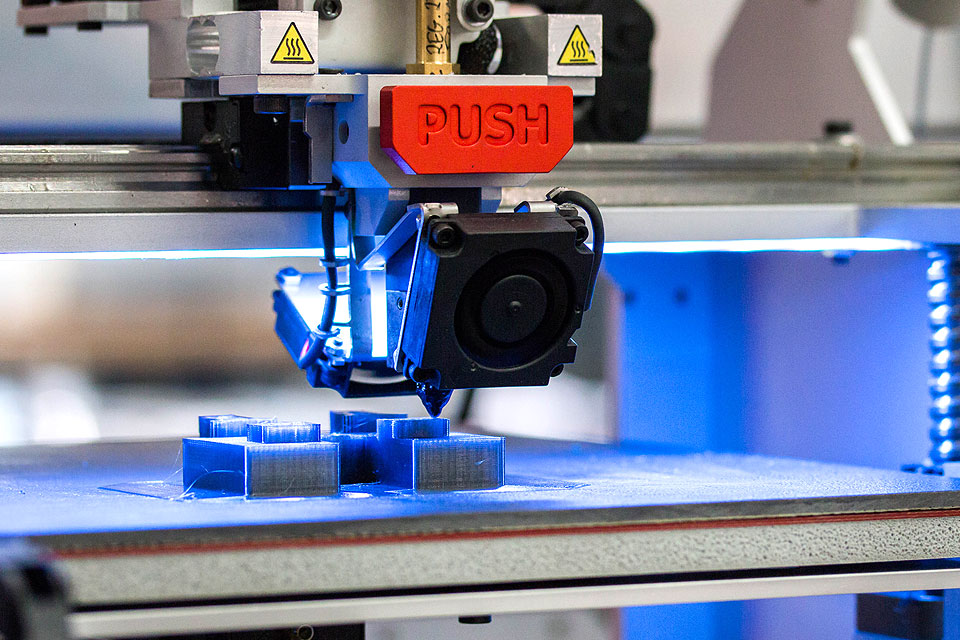

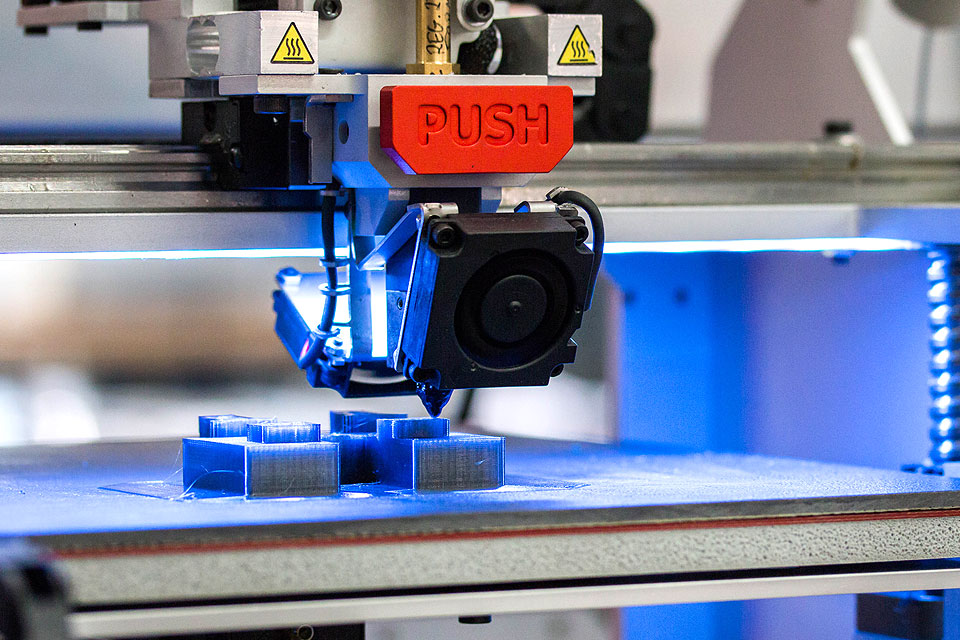

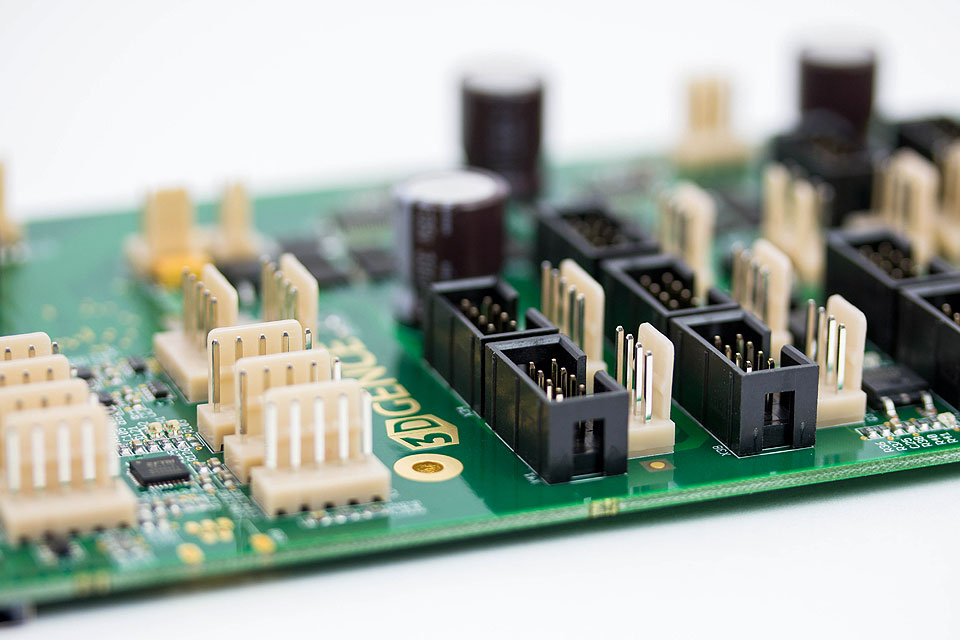

Benutzer von professionellen 3D-Druckern suchen nach einer Druckplattform, die die Freiheit der Materialauswahl bietet, die hohe Qualität von 3D-Drucken gewährleistet und lange und zuverlässige Vorgänge ermöglicht. 3DGence ONE ist mit einem patentierten PUSH-System ausgestattet, das einen schnellen Hotend-Wechsel zugunsten einer einfachen Bedienung ermöglicht. Spezielle Elektronik sorgt für die automatische Kalibrierung des 3D-Druckers. Spezielle Sensoren scannen das Heizbett und beseitigen mögliche Probleme mit dem Druckprozess.

Die beste Druckqualität wird durch den Einsatz von gebrauchsfertigen Materialien erzielt, die in der ständig erweiterten Materialdatenbank gespeichert werden. Die industrielle Druckerbauweise sowie die fortgeschrittenen Programmfunktionen erlauben die Materialprofile an die Bedürfnisse professioneller Benutzer anzupassen.

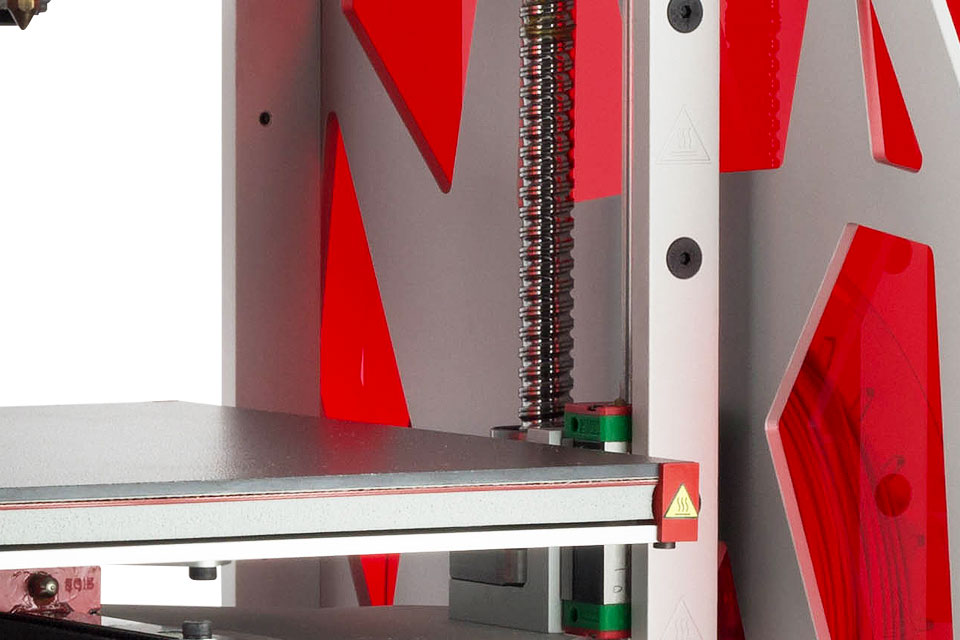

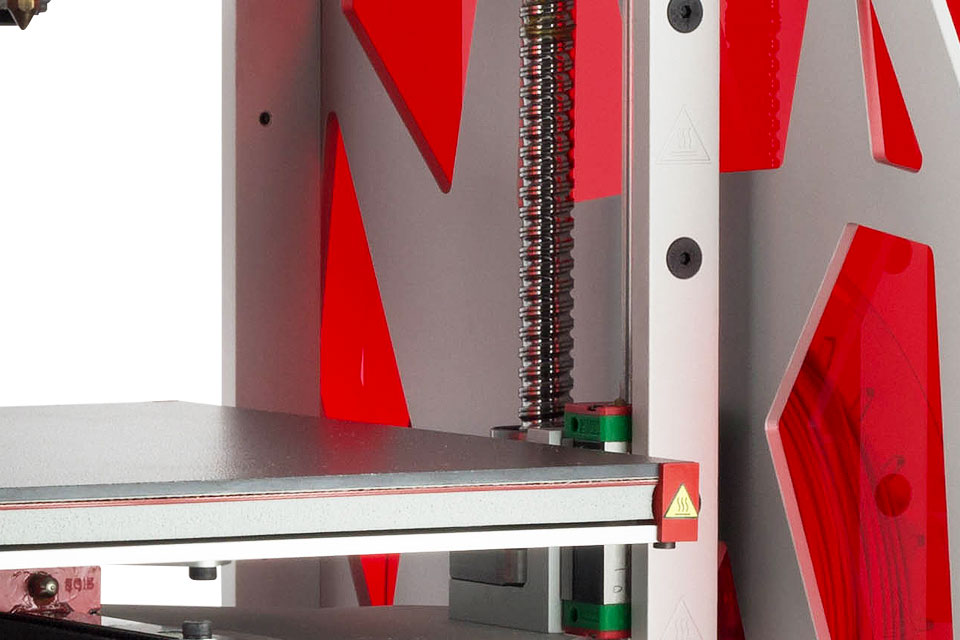

Durch den Einsatz von Sondersensoren scannt das Gerät den Arbeitstisch und speichert die Punkte, deshalb können jegliche Abweichungen an der Oberfläche problemlos erkannt werden. Eine solche Lösung sorgt für die erhebliche Verbesserung der Qualität und eliminiert die künftige Haftung der Ausdrucke auf der Oberfläche.

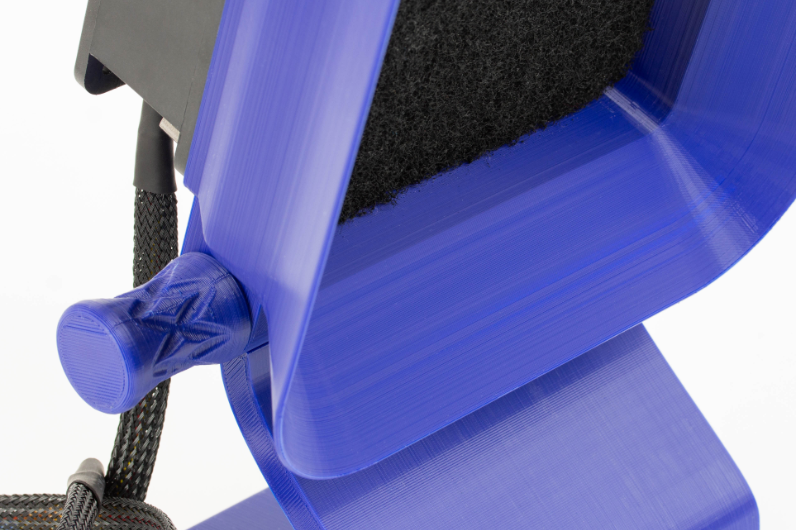

PUSH – System zum schnellen Kopfwechsel. Mit dieser Lösung können die Köpfe nur in einigen Sekunden ohne Werkzeuge gewechselt werden. Außerdem kann der Drucker an die aktuellen Bedürfnisse des Benutzers angepasst werden.

Entfernen Sie einfach 3D-Ausdrucke

Bietet eine sehr gute Haftung beim Drucken – ermöglicht eine nahtlose Trennung von Gegenständen vom Arbeitsbereich. Es hinterlässt eine strukturierte Oberfläche neben der Tabelle am unteren Rand des Ausdrucks.

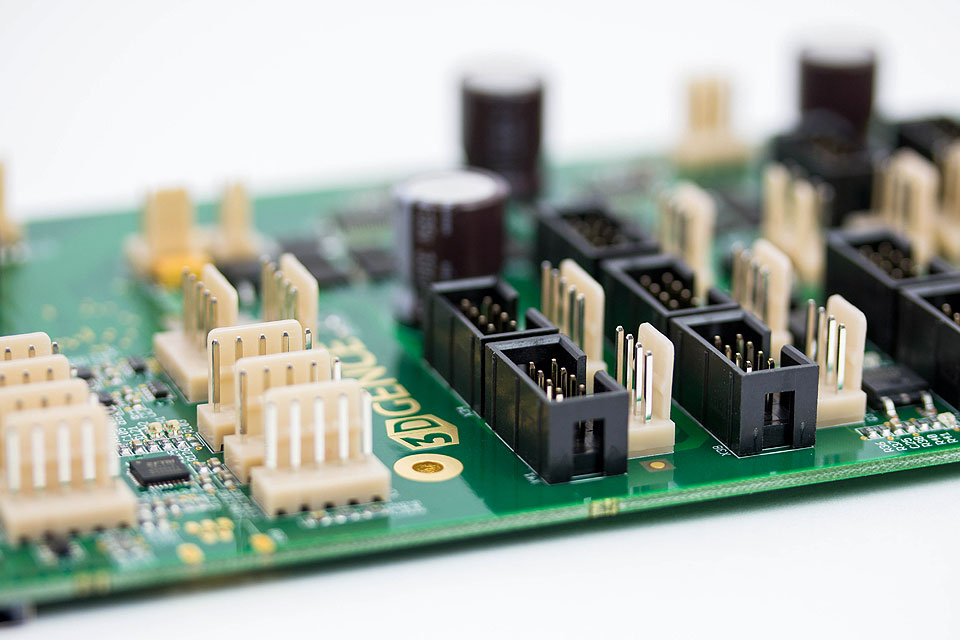

Mögliche Anpassung der dem Motor zugeführten Leistung je nach dessen Drehzahl.

3DGence Titanium verfügt über:

– 2 Wärmeschutzstufen der Düse,

– 3 Wärmeschutzstufen des erwärmten Arbeitstisches.

Die Elektronik wird zusätzlich mit einem Stromkreisschutz sowie einem Überlastschutz ausgestattet.

Der 3D-Druck wird in der Medizin zunehmend eingesetzt und ermöglicht eine detaillierte Planung von Operationen.

The construction of a prototype form is a long-term process, and the implementation time is very important. Check what goals Geo Globe Polska achieved thanks to the 3D printing technology.

Die Verwendung von 3DGence INDUSTRY F340 ermöglichte die Überprüfung des Prototyps von Presskollektor, der eines der Elemente ist, aus dem die Hydraulikpumpeneinheit des Feuerwehrwagens besteht.

Durch den Einsatz von 3D-Druckern konnten die Baumodelle unter Aufrechterhaltung ihrer ursprünglichen Form und Proportionen hergestellt werden, wobei der aktuelle Gebäudezustand mit dem Projekt verglichen werden konnte.

Electric auto-revolution can be supported by 3D printing technology! Using 3D printer AGH Racing could test original design of steering knuckle at a very low cost and in just two days.

ABS ist einer der beliebtesten thermoplastischen Kunststoffe, unabhängig von der Produktionstechnologie.

Bietet ausgezeichnete Druckqualität, hohe Ermüdung, mechanische Festigkeit und gute thermische Beständigkeit.

Biologisch abbaubares thermoplastisches Polymer, das aus nachwachsenden Rohstoffen hergestellt wird.

3D-Drucktechnologie

FFF

Arbeitsraum

235 × 255 × 195 mm (11 685 cm3)

Schichtauflösung

50 μm

Anzahl der Druckköpfe

1

Düsendurchmesser

0.4 mm

Durchmesser des Filamentes

1.75 mm

Temperatur des Druckkopfes

265°C

Temperatur des Druckbettes

160°C

Material

PLA, ABS, ASA, TPU, HIPS

Erforderlicher Anschluss

230V AC

Max. Stromaufnahme

600W

Mittlere Stromaufnahme

220W

Kommunikation

USB, SD-Karte

Drucksoftware

3DGence SLICER 4.0